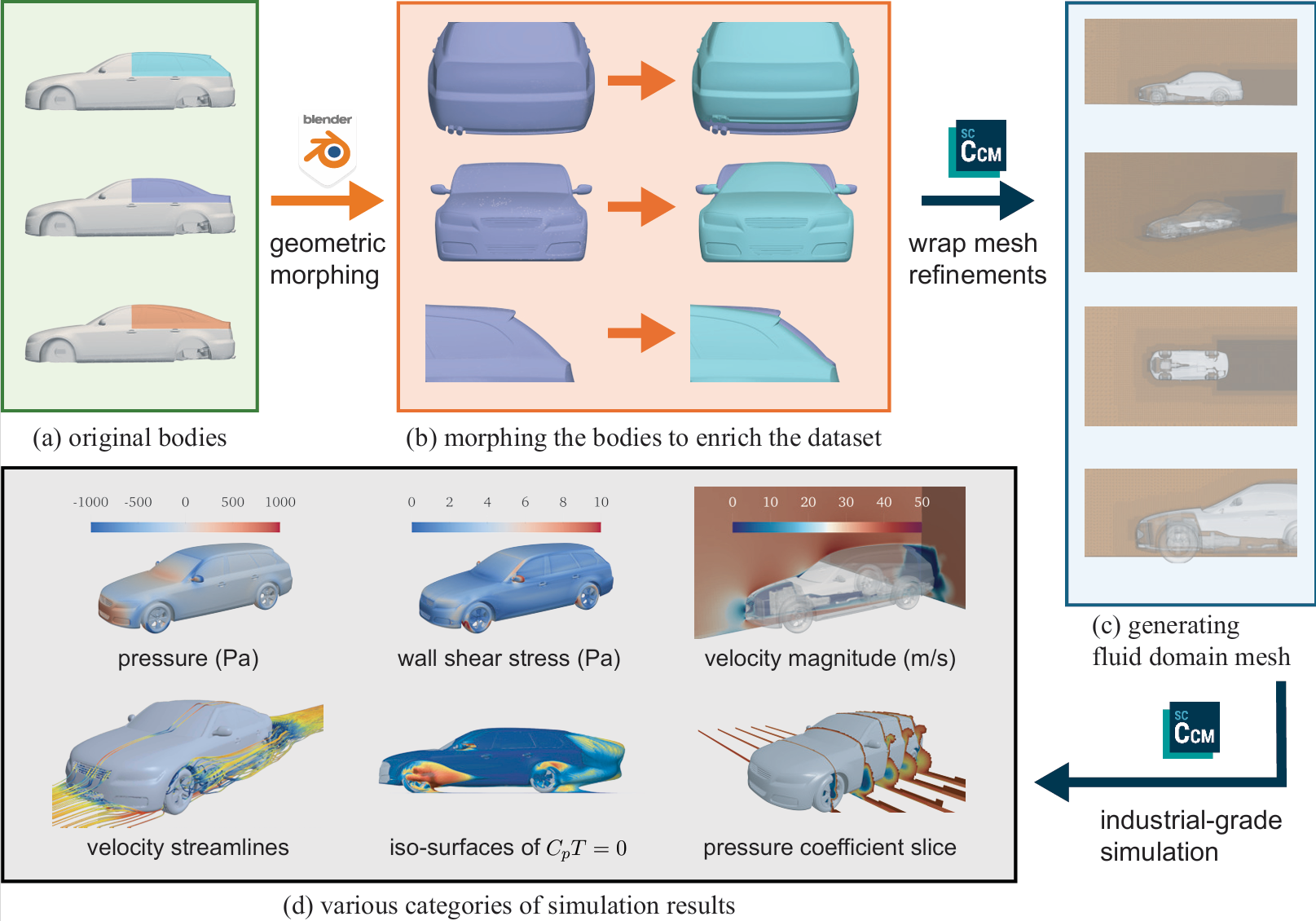

Figure 1: DrivAerStar Dataset Overview

DrivAerStar data generation. (a) Three canonical DrivAer reference bodies (Estateback, Notchback, and Fastback) serve as geometric foundations. (b) Parametric morphing systematically varies 20 vehicle components, including greenhouse (top), rear diffuser (middle), and trunk lid (bottom). (c) Industrial-grade mesh generation in STAR-CCM+® produces refined hexahedral-dominant meshes with precise wheel alignment and boundary layer resolution for complex flow capture. (d) Comprehensive CFD simulations generate diverse flow visualizations: surface pressure, wall shear stress, velocity magnitude, streamline patterns, flow separation regions (\(C_P=0\) iso-surfaces), and pressure coefficient slices revealing key aerodynamic structures.

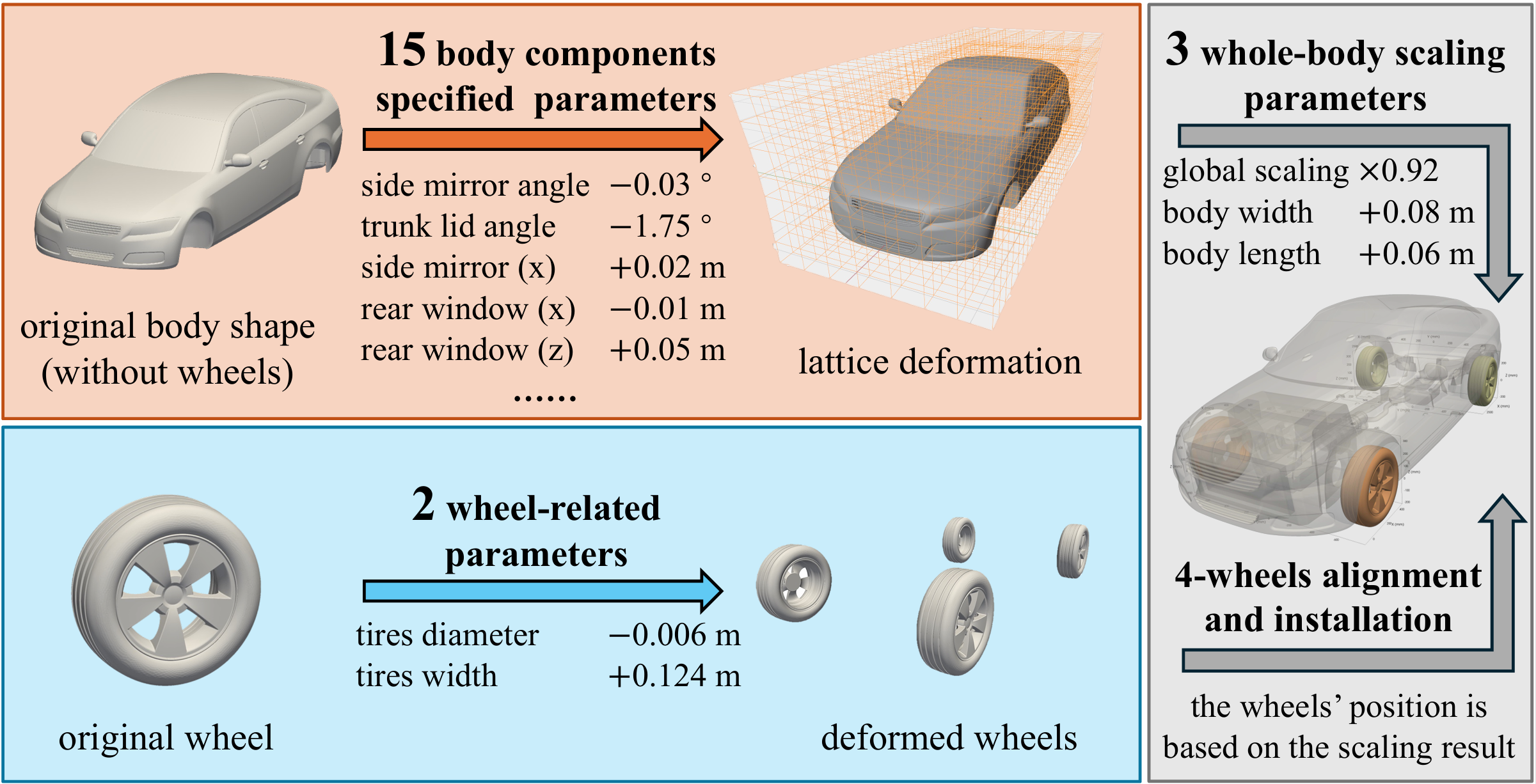

Figure 2: Geometric Morphing Pipeline

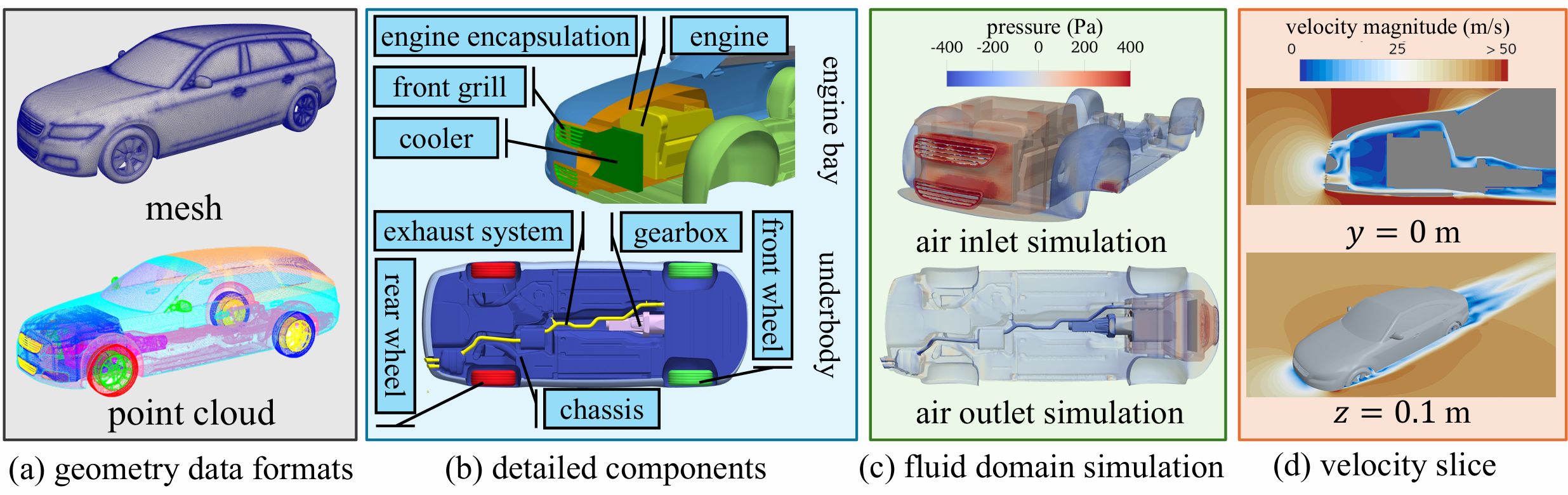

DrivAerStar dataset features. (a) Multiple geometry data formats: mesh (top) serves as primary representation while point cloud (bottom) enables alternative computational approaches and geometry analysis. (b) Complete vehicle modeling includes detailed engine bay compartment assembly (top) and underbody components (bottom), distinguishing DrivAerStar from previous automotive datasets. (c) Internal airflow simulation capabilities featuring air inlet (top) and outlet (bottom) simulations, enabled by precise internal component modeling to support comprehensive automotive system research. (d) Velocity field cross-sections showing internal engine compartment flow at vehicle centerline (\(y=0 m\)) and external flow field at tire axle plane (\(z=0.1 m\)).

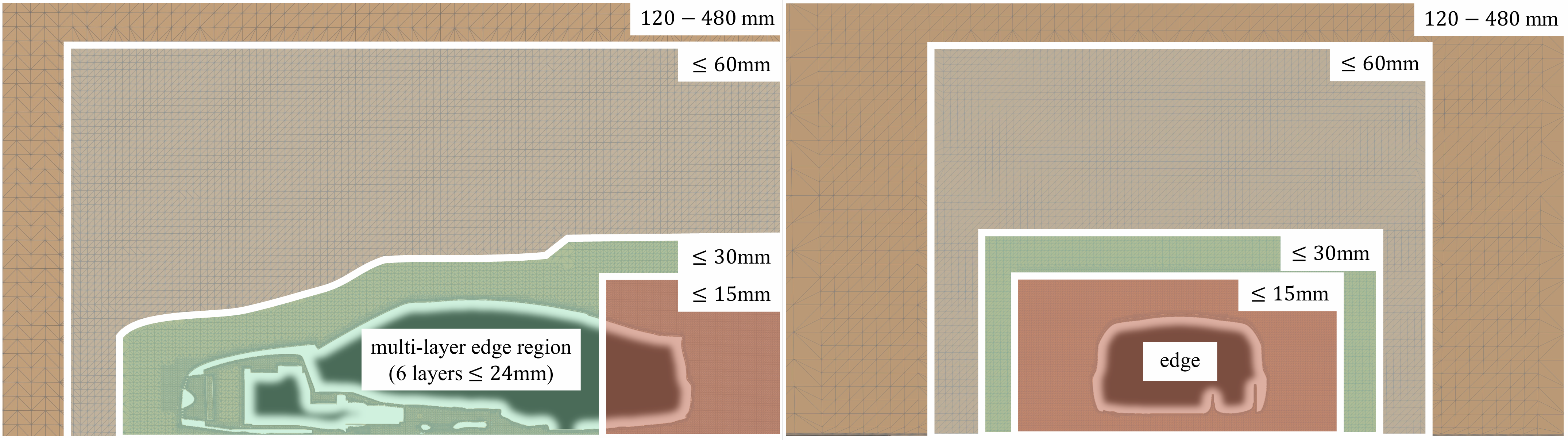

Figure 3: Mesh Strategy and Wind Tunnel Validation

Figure 3:Geometric morphing pipeline example. Our parametric deformation framework transforms the baseline model through three sequential operations: (i) Body component morphing (top-left) applies 15 controlled parameter adjustments, including dimensional modifications and component repositioning; (ii) Wheel morphing (bottom-left) enables precise tire parameter control; and (iii) Whole-body scaling and wheel installation (right) applies 3 scaling parameters while aligning wheels to scaled positions. This systematic FFD approach generates geometrically diverse yet aerodynamically realistic vehicle configurations.

Figure 4: Internal Flow and Multi-Physics Results

Cross-sectional views of mesh generation strategy. (a) Longitudinal section at \(y = 0 \, \text{m}\) shows four nested refinement zones with progressive cell density: far-field (120-480 mm), intermediate domain \((\leq 60 \, \text{mm})\), near-body region \((\leq 30 \, \text{mm})\), and high-resolution zone \((\leq 15 \, \text{mm})\) surrounding the vehicle. Dedicated 6-layer boundary layer refinement with total thickness under 24 mm captures viscous phenomena. (b) Transverse section at \(x = 3.12 \, \text{m}\) demonstrates consistent refinement strategy with graduated cell density approaching vehicle surfaces, enabling accurate wake structure resolution while maintaining computational efficiency.

Figure 5: Machine Learning Benchmarks

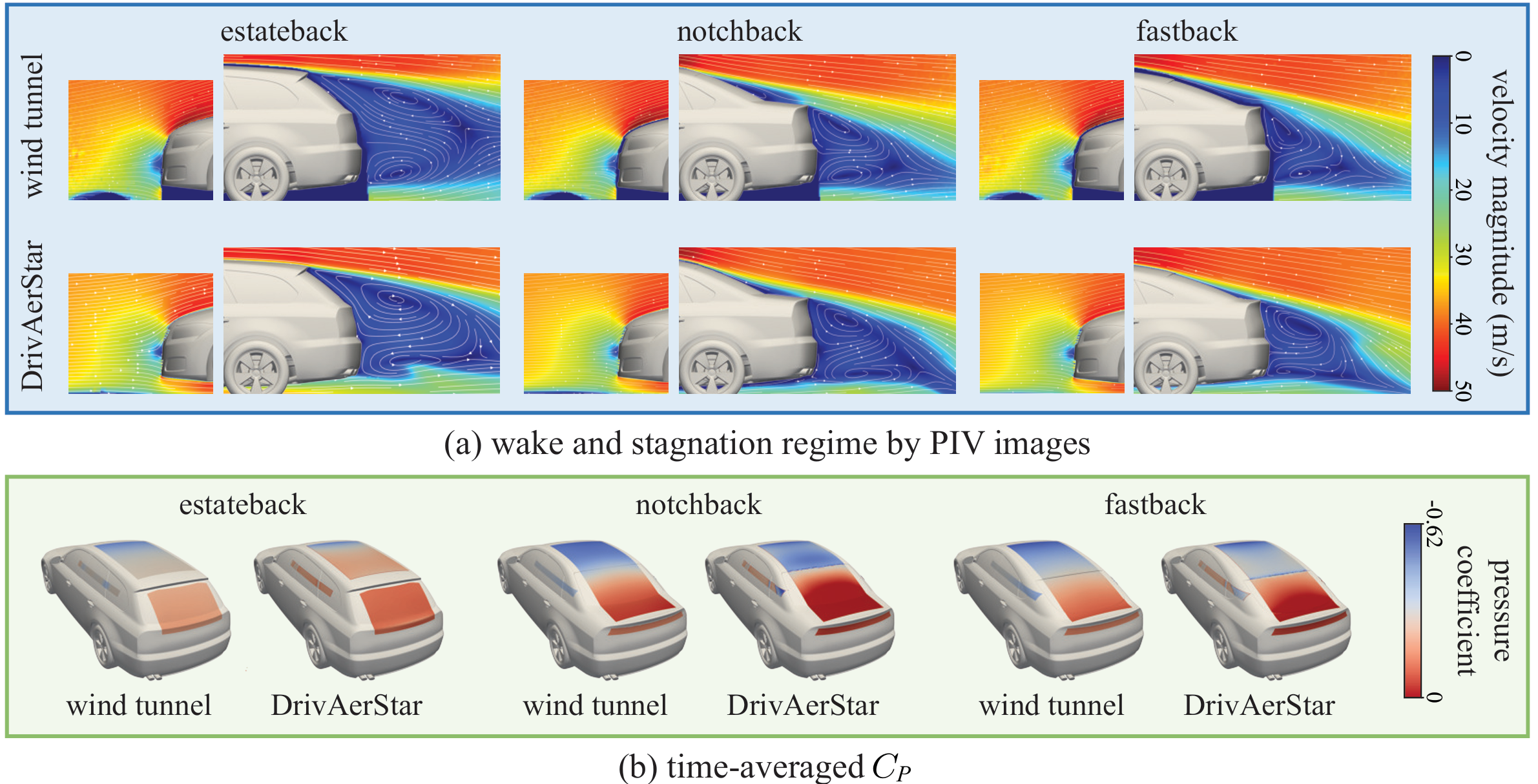

Validation of flow physics predictions against wind tunnel measurements. (a) Velocity magnitude distributions compare wind tunnel PIV measurements (top row) with DrivAerStar predictions (bottom row) in wake regions and stagnation zones, demonstrating excellent flow structure agreement. (b) Surface pressure coefficient (\(C_P\)) distributions across vehicle body surfaces show consistent prediction accuracy between experimental and computational results for all three vehicle configurations, confirming accurate capture of complex aerodynamic phenomena.